Airborne Motorworks patented EGP (Electromagnetic Gyroscopic Propulsion) motor is adaptable to a broad range of applications. In the commercial sector there is increasing emphasis on utilizing zero emission, sustainable energy products.

One of the heaviest users of energy in the commercial sector is air handler drive applications found in heating, ventilation and air conditioning (HVAC) units. HVAC is present in everything from commercial office buildings, manufacturing plants, to mining operations.

Our industrial business unit is leveraging the high torque, compact size, and low heat emissions of our EGP technology to create an ideal solution that industry not only needs to improve HVAC efficiency, but demands so they maintain compliance with current and upcoming governmental regulations.

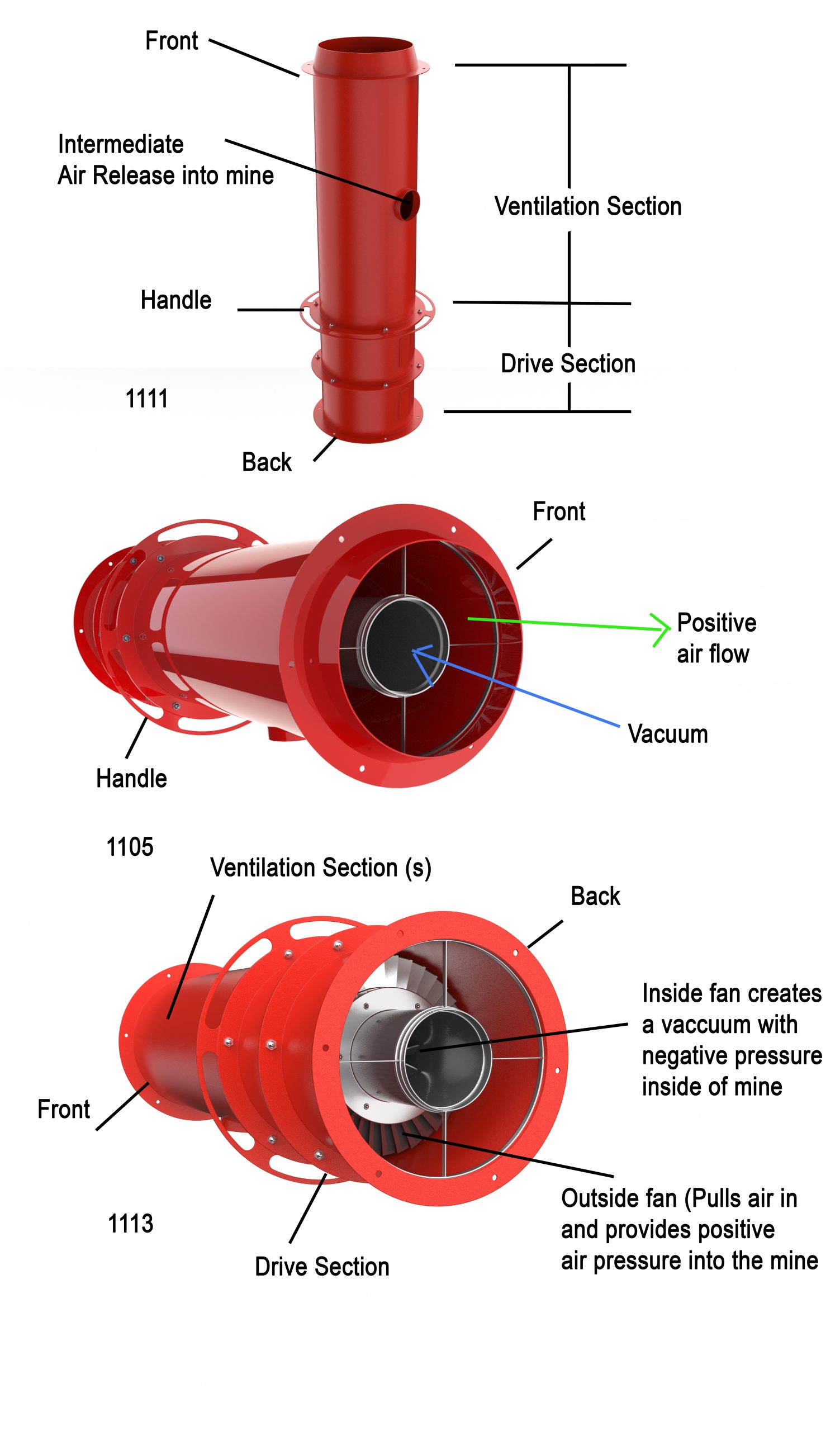

We are currently working with an industry leading innovator in the minerals mining industry to develop a lightweight, flexible air blower system for deep level mining.

The key components of the system remain above ground in order to mitigate noise and heat at the work level while also not taking valuable space from the mining site. The air handler acts to rapidly remove the stale air and dust associated with below ground operations and simultaneously replace it with fresh air (the system is bi-directional) thereby enabling more productivity at the mining site.

The AMW air handling system is designed both as original installation equipment and as an off-the-shelf viable replacement for retrofit into existing applications.

Like other uses of AMW motor technology, the air handling system performs with remarkably higher efficiency and torque density than conventional systems and also at low heat generation. It is clearly a “green technology” that can be powered by a number of energy sources from stored energy to electrical power connections such as the AMW wind turbine.

By utilizing the benefits of EGP, our air handlers can potentially increase the amount of air flow delivered by the same sized air handlers that are in use today. The chamber becomes the driving force of the rotors, greatly reducing the overall parts count while increasing efficiency. The market doesn’t just want this technology, they are demanding it to keep up with emerging Net Zero and other emerging environmental initiatives.